EtaPRO® VirtualPlant™ – Thermal Performance Monitoring

EtaPRO® VirtualPlant™

Improve Asset Performance with

EtaPRO® VirtualPlant ™

The leading thermal performance management technology

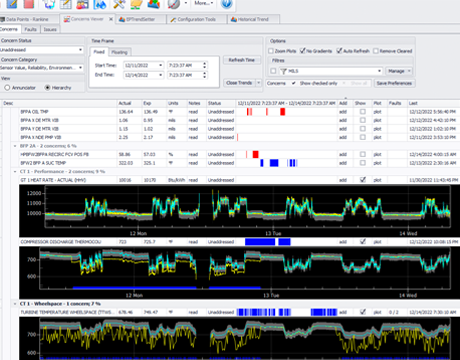

EtaPRO VirtualPlant [493kb] is a leading technology for building first principles thermodynamic models of power plant cycles. Accelerate your plant’s performance using real-time benchmarks from design and acceptance test data with VirtualPlant.

Empowering best-achievable asset performance

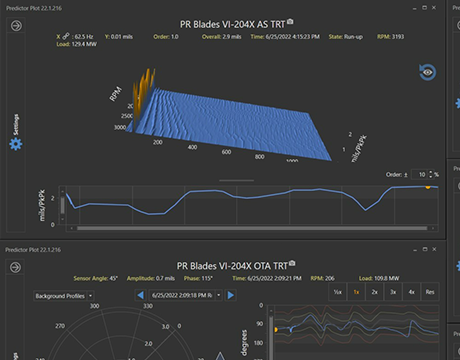

Energy companies count on EtaPRO VirtualPlant [493kb] for an accurate understanding of how ambient, operating and equipment condition affect overall plant performance. This powerful “what-if” tool provides quick insight into how operating, maintenance and capital improvement decisions can increase productivity and efficiency.

Why Choose EtaPRO® VirtualPlant™?

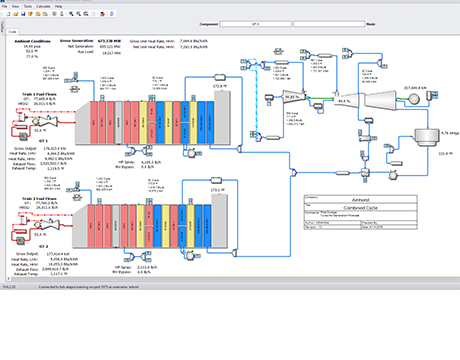

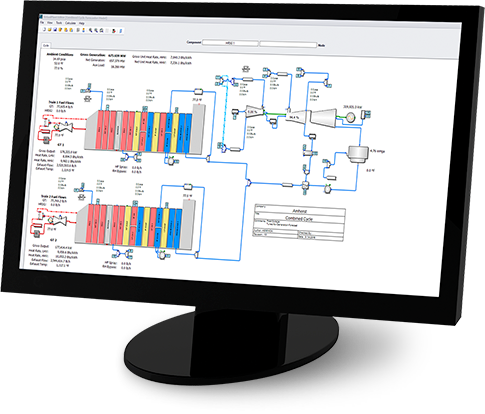

With EtaPRO VirtualPlant, your engineers can quickly and easily quantify the impact of changes in equipment condition and operating decisions. VirtualPlant integrates power cycle components into an integrated, physics-based digital twin to represent the overall plant. VirtualPlant models are a powerful extension of the mass and energy balances provided by plant designers. Engineers have the flexibility of easily adjusting the model to reflect actual operating conditions, making them better suited to the everyday needs of owners and operators.

“What-if” analyses

VirtualPlant allows the impact of degradation measured and detected by EtaPRO to be quickly and accurately quantified. VirtualPlant model components are characterized by original design information, with options to incorporate common sources of degradation, making it easy to quantify their impact on overall plant capacity and efficiency. What normally takes hours with rule-of-thumb estimates can be accomplished accurately and in minutes with VirtualPlant.

Easy-to-use interface

VirtualPlant’s drag-and-drop cycle builder is easy to use with purpose-built data entry forms for streamlined model creation. A comprehensive library of power plant components is included to quickly model traditional Rankine, Brayton and combined cycles. Multiple models can be combined to predict overall plant or enterprise capacity and efficiency. Connect to your EtaPRO system for real-time boundary conditions and model inputs.

Perform parametric studies in Excel

You can run VirtualPlant models in the cycle builder to see immediate results or use the VirtualPlant Excel add-in to run 100’s of cases in a batch mode. This is useful for preparing mass and energy balances at various conditions, determining performance sensitivity factors for use in other applications, or creating full thermal kits. The VirtualPlant Excel add-in puts you in full control of your model runs.

Reliably run thermodynamic digital twins in real-time

With nearly two decades of on-line digital twin experience, we know what it takes to deliver reliable convergence throughout your plant’s operating range. VirtualPlant models run in their full native format, without modification or simplification, to deliver accurate and highly granular results. Real-time models are used throughout your EtaPRO System to predict expected results, correct actual results to reference conditions, and provide powerful data validation and substitution when needed.

Learn more about EtaPRO® VirtualPlant™

EtaPRO® Features

EtaPRO™ Archive™

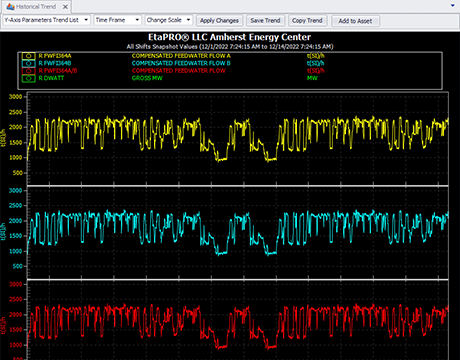

- High speed data historian

- Event counting (starts, stops)

- Equipment operating hours

- Hours of operation above specified conditions

- Ad-hoc trend & analysis

Our Customers

What People Are Saying

Hear from the clients we strive to delight every day so they can achieve excellence.

INNOVATIONS & INSIGHTS

Learn From Experts

Innovation has always been a critical part of our DNA. Helping our clients succeed drives our spirit of innovation and continuous improvement.